Sealabilty of flexible packages are mainly indicated by integrality of packaging bags and sealability of heat seal edges. The most widely used technology in flexible package manufacturing is heat seal at present, so heat seal strength is used as index of sealabiligy of heat seal edges. The positions that different materials connects together are usually the weakness of packaging sealabilities, the purpose of testing heat seal strength of flexible package is to guarantee that sealability of heat seal edge is the same as the rest part of packaging bag at least. But in practical application, there is no a common recognition about how to get heat seal strength that indicates sealability of flexible package in test. This paper introduces the differences between expansion heat seal strength and tension heat seal strength and advantages of restraining plates tester.

1.Heat Seal Strength Test

According to testing methods, heat seal strength of materials can be classified into tension heat seal strength and expansion heat seal strength. Tension heat seal strength that get from tension tester is the ability that heat seal edges resist disconnection under consistent and even forces (for example, peeling). It is suitable to evaluate the opening properties of flexible packages. But in pactical applications, leaks at heat seal edges of flexible packages is mainly arised by pressures in bags. The directions and values of pressures are not the same as that in tensile tests, and materials that nearby heat seal edges may be distortion. This can be simulated by increasing pressures inside packaging bags, expansion heat seal strengths that are gotton in this way are the most representative of practical heat seal strengths and weaknesses of heat seal edges can be detected in the same way. However expansion heat seal strength can not represent average heat seal strength so it is not relevant to tension heat seal strength.

2.Advantages of Restraining Plate Test

Expansion heat seal strength is relevant to size, shape and material of packaging bag, but some especially soft packaging matericals(it is well known that ,some materials that possess high tensile strength and distortion tatio, can be tensioned many times to their primary lengthes.) distort as pressures increase and bring more difficulties to expansion heat seal strength tests. The design of restraining plate is intended to solve these problems. Restraining plate restrains expansion and distortion of material of flexible packaging bags, it shifts pressures to heat seal edges and increases the uniformity of pressures.

Application of restraining plate tester makes expansion heat seal strength of flexible packages more accurate and reasonable, and its testing environment is comparatively similar to practical applicable enviornment. Flexible packages are mainly used in food ,medicine, cosmetic, daily chemistry and electrical components, gases in packaging bags often form a guaranteed ballonet to contents in bags after sealing. These flexible packaging bags are often piled up together in transportation and storage, the pressures of packaging bags are different from that of free expansion in this occasion, but close to that with restraining plate. Restraining plate could restraint expansion and distortion of packaging bags accurately and quantificationally, reducing pressures the films suffer and distributing pressures to heat seal edges of packaging bags concentrately and evenly. The testing results are closer to practical transportations and storages of flexible packages therefore packaging manufacturers and customers paid more attention to it.

3. LSSD-01R restraining plate tester

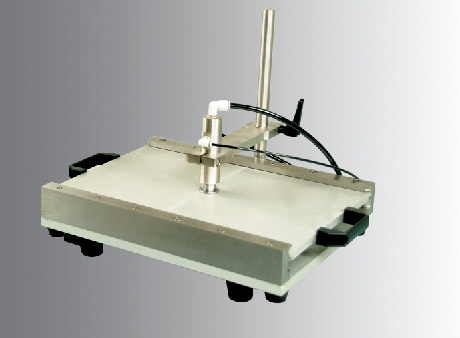

The LSSD-01R restraining plate tester of Labthink LSSD-01 leak and seal detector is applicable in the measurement of heat seal strength, the quality of heat seal, the burst pressure and the seal-leakage character of each heat seal edges of the flexible packages such as food, medicine and flexible packages that are made using various kinds of heat seal technics. It can also provide index evaluating and analysing for the compression and burst resistance strength of the flexible packaging materials. The limit height of restraining plate is designed in strict accordence with the relevant standards, replace freely and operate easy. By adopting restraining plate, the load to each part of the samples could be even and on the safe side. Combining with burst test, creep test and creep to failure test, it can test leakage index and creep index under bursting pressure and load pressure of flexible packages

Fig 1. restraining plate tester

Process of restraining plate test is not complicated, concrete steps are as follow:

First, select testing method according to executive standard and decide whether to apply restraining plate tester or not.

Second, prepare specimen and select an appropriate distance between restraining plate according to the size of specimen

Third, prepare restraining plate tester and put specimen into tester. Seal the position that probe inserted carefully.

Fourth, start tester, then select test mode and set parameters according to testing objects. Start testing and puff air into flexible package to increase pressure.

Fifth, testing results are give out automatically.

When testing with restraining plate tester, distance between restraining plates may effect testing result and need special attention. The larger the distance between restraining plates, the smaller the pressure on the heat seal edge and the larger the pressure that brings distortion of material. So in order to unify testing conditions, above 60% of surfaces of flexible packages must touch restraining plates directly and methods of testing distance between restraining plates are regulated carefully.

4. Conclusion

Small packageing bags are flexible packages usually. Heat seal strength test relates to sealability of content in packaging bag directly and is the premise of maintaining contents in package. Compares with tension heat seal strength, expansion heat seal strenght testing is more valuable in practice. Traditional testing method of free expansion may decrease practicability of testing results because of expansion of flexible packaging bags. We can reduce pressures that imposing on films and distribute pressures on the edges of flexible packages more evenly and concentrating with the help of restraining plates. The testing results are closer to practial transportations and storages of flexible packages and thus possess more practical values.