Many believe that the existence of gas pressure difference in differential-pressure method would affect the structure of macromolecule polymer of flexible packaging and further affect the results of gas penetration test: gas penetration amount and gas penetration coefficient (the multiply of gas penetration amount and thickness of film). However through a year’s experiments and investigations, we have found that this point of view is not right and demonstrated that the evidence is insufficient, unscientific and incorrect.

1. Definition of Gas Penetration Amount

The misunderstanding of the definition of gas penetration amount is a key factor which leads to the mistaken view that the existence of pressure difference would affect the gas penetration property of material by gas penetration amount. According to the definitions in standards GB/T 1038 and ASTM D1434, gas penetration amount (gas transmission rate) is the volume of gas penetration in unit area of specimen in unit time after gas penetration is stable under the constant temperature and unit pressure difference; the unit commonly used is cm3/m2·d·atm. We can see from analysis that gas transmission rate in standard ISO 2556 is consistency with gas penetration amount. Gas penetration coefficient which represents material property, is the multiply of gas penetration amount and thickness of film.

Flows and currents may increase as hydraulic pressure and voltage increase. It is inclined to get the conclusion that gas penetration amount is affected by gas pressure difference, according to the pattern above. But “under the unit pressure difference” which defined in the gas penetration amount, demonstrates that the pressure difference in two sides of specimen is rigidly regulated when calculating gas penetration amount. This can be seen from formula that compute gas penetration amount, so gas penetration amount, from which gas penetration coefficient is derived, would not be affected by the variation of pressure in concrete experimental procedure.

2. Pressure Difference and Material Structure

Film materials have been vividly compared to sponge. It is considered that when pressure increases, the microstructure of film can be affected and would change from loose structure to compact structure and thus, increase the difficulty of gas penetration. If this point of view is correct, the thickness of film would reduce as time goes by. Supposing the compactness of structure would increase the difficulty of gas penetration, the data of gas penetration test would decrease as the time of constant tests increase. Labthink has designed a series of tests to validate this point of view. We selected aluminum foil composite film, PET film and PC film, the gas penetration properties of which belong to the range of high barrier, middle barrier and low barrier respectively; and tested the gas penetration of the same specimen for many times to inspect the repeatability of constant testing results and the changes of thickness before and after testing, as illustrated in table 1. Testing results demonstrated that the data of gas penetration test did not change basically and the thickness of specimen did not change after the experiment. This proves that gas pressure difference would change the structure of material from loose to compact was incorrect.

Table1. Data List of Oxygen Penetration Amount and Specimen Thickness

| Specimen | Gas Penetration Test | Thickness Test(μm) | ||||||

|---|---|---|---|---|---|---|---|---|

| Oxygen Penetration Amount(ml/m2·24h·0.1MPa) | Temperature | CV(%) | Before Test | After Test1 | Δd | |||

| Aluminum Foil Composite Film | 0.150 | 0.202 | 0.179 | 27°C | 14.72 | 97.9 | 97.9 | 0 |

| PET Film | 58.467 | 58.770 | 60.291 | 30°C | 1.65 | 25.6 | 25.7 | 0.1 |

| PC Film | 521.122 | 536.198 | 529.115 | 30°C | 1.43 | 128.3 | 128.3 | 0 |

Tips: 1. the measurement of thickness is done within the scope of valid test area, other areas which are polluted by vacuum ester, are of little significance to be measured.

The mechanical properties of film materials are fairly well and are the basis of wide applications. Compressive strength of film material is the max strength imposed on the unit section when material is not destroyed under the slowly imposing of pressures. The compressive strength of PP is 39 MPa ~56MPa, ordinary PS is 80.5 MPa ~112MPa, modified PS is 28 MPa ~112MPa, PA-66 in dry condition achieves 120MPa. We can see that the compressive strength of film materials are hundreds, even thousands times of the pressure differences imposed on specimen in differential-pressure method tests. And in testing sealing property of flexible packaging, we have found that the break points of flexible packages with break pressures about 0.1MPa as well as above 0.15MPa are usually on the edge of hot sealing. Higher pressures are needed to make breaks in films, but perforated papers in the side of low pressures protest and support specimens well, so the existence of pressure difference would not affect the structure of specimen in differential-pressure test.

3. Pressure Difference and Gas Penetration Property of Material

Would the gas penetration property of material be affected by pressure difference? Even if the suspicions that pressure difference would affect material structure are excluded, many still believe that the existence of relationship between pressure difference and gas penetration property. This point of view can be demonstrated through experiments: if the gas penetration amount and gas penetration coefficient do not change whereas pressure difference between two sides increases, it can be proved that the existence of pressure difference do not affect the gas penetration property of materials.

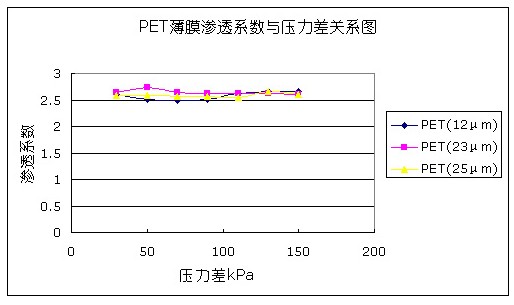

Labthink has tested tens of specimens of eight kinds under different gas pressure differences for months. The test points of pressure differences is 0kPa、50kPa、70kPa、90kPa、110kPa、130kPa、150kPa, the gas penetration amount of testing materials are ranging from 1.5cm3/m2·24h·0.1MPa to 7000cm3/m2·24h·0.1MPa. figure 1 is the penetration coefficient testing curves of three PET materials of different thickness: PET(12μm), PET(23μm) and PET(25μm). Testing data demonstrated that the changes in pressure differences did not affect the gas penetration amount and penetration coefficient of specimen. Monograph based on the test had been published in IAPRI 2007, the conclusion that pressure differences did not affect gas penetration property of materials, was affirmed and agreed by professionals and specialists from many countries.

Fingure1 Relation Graph of Penetration Coefficient and Pressure Differernce of PET Film

Unit of penetration coefficient:(E-12)cm3·cm/cm2·s·cmHg

Some people may consider that the pressure difference in our test is not broad enough and far from the limit of compressive strength of film material. Not to come singly but in pairs, in 2007, IAPRI members from Chile did the similar research and came to the same conclusion with us. The research that is described in the paper “INFLUENCE OF HIGH PRESSURE PROCESSING OVER MECHANICAL, THERMAL AND BARRIER PROPERTIES ON FLEXIBLE FOOD PLASTIC PACKAGING” issued by the Chile delegates enhanced the pressure to 400MPa, that is, 4000 times as high as the pressure in differential-pressure method and did special research to the barrier property of special coat material. The conclusion is that as to metallization materials and silicon oxide plated films, their barrier property is affected (40% to 50%); but as to PE/EVOH/PE and PET/PE materials, the data from its barrier property tests does not change obviously. Considering the fact that the pressure in the HPP is 4000 times as high as the pressure in differential-pressure test and beyond the limit of compressive strength of film materials, coated material keeps good barrier property under high pressure, it’s obvious that the gas penetration property of materials won’t be affected by the existence of pressure difference in differential-pressure test.

4. Conclusion

Generally speaking, the view that pressure difference affects the gas penetration property of materials and even includes mistaken understandings in parameter definition can not stand actual testing. Any lab would come to the same conclusion with Labthink, if it does the similar experiment. The whimsicality that data would not be affected in isopiestic method because of the absence of pressure difference, and data would be affected in differential-pressure method because of the existence of pressure difference, is absurdity and absolutely err from the scientific and careful attitudes towards research.