Permeability Test Instruments

Labthink's Permeability Test Instruments provide precise measurement solutions for assessing barrier properties of packaging materials.These instruments evaluate the transmission rates of gases such as oxygen, water vapor, and carbon dioxide, delivering critical barrier data needed for film analysis. Our advanced permeation testers ensure compliance with international standards, making them ideal for quality assurance in the pharmaceutical, food, and other demanding industries.

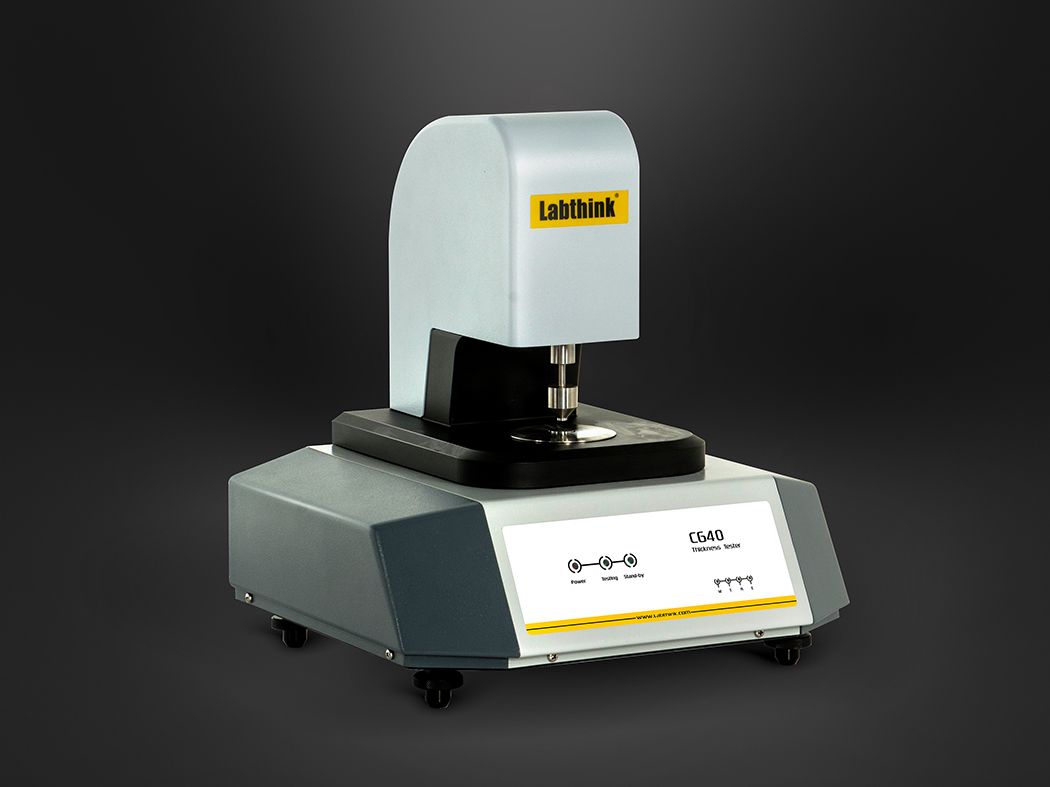

Non-Permeability Test Instruments

Labthink's Non-Permeability Test Instruments focus on evaluating the physical properties of packaging materials.These instruments perform tests such as leak and seal integrity assessments, tensile strength, heat seal strength, and COF measurement. Designed for rigorous quality control, our instruments are indispensable for testing packaging material and integrity. Our comprehensive testing solutions ensure that packaging meets the highest standards of safety and performance.