The landscape of modern packaging is governed by complex technical standards designed to ensure product quality, safety, and material compatibility. Across this system, two of the most influential ones are the International Organization for Standardization (ISO)and ASTM International (formerly the American Society for Testing and Materials). While these organizations operate under different governance and structures, their most important function for industry is to provide reliable, repeatable testing protocols.

This article examines specific standards used across flexible packaging and materials science, demonstrating how ISO and ASTM often develop functionally equivalent standards that share highly similar requirements, ensuring technical alignment and quality control.

1. Scope, Governance, and Global Reach

The fundamental distinction between the two organizations lies in their organizational mandates. ISO operates as a global body, made up of national standards organizations from over 160 countries. ISO standards are established through a rigorous consensus process among member nations.

ASTM International has a strong regional focus, originating in North America, though its standards are widely referenced globally. ASTM's structure allows parties of interest—from industry scientists to academics—to participate

directly in writing the standards. This model makes ASTM highly industry-driven and focuses on specific, technical methods related to materials, products, and processes.

2. Technical Equivalence in Material Testing

Despite their different origins and governance, in highly technical fields like materials and packaging science, ISO and ASTM standards frequently describe the same testing procedure. This is particularly evident in barrier property testing, which is critical for packaging. For instance, ASTM D3985 and ISO 15105-2 are considered technically equivalent, meaning a material tested according to one standard will yield results recognized under the other, provided the environmental conditions (temperature, humidity, etc.) are identical.

Oxygen Transmission Rate (OTR): ASTMD3985 and ISO 15105-2

For measuring a film's barrier against oxygen, the two standards are the ASTM D3985 and ISO 15105-2. Both standards specify the use of the Coulometric Sensor Method (also known as the Equal Pressure method). This principle measures the precise volume of oxygen gas (cm3) that permeates through a unit area of film (m2) over a unit of time(day). ASTM D3985 is the North American standard specifically named for this OTR test, while ISO 15105-2 is the international framework that defines this Equal Pressure sensor method for gas transmission in general, but is predominantly applied to oxygen measurement.

Water Vapor Transmission Rate (WVTR): ASTM F1249 and ISO 15106-2

Similarly, for testing a material's barrier against moisture, the two equivalent standards are ASTM F1249 and ISO 15106-2. Both standards mandate the use of the Infrared Sensor Method. This highly accurate and automated technique measures the mass of water vapor (g)that passes through the material's surface area (m2) over 24 hours(day). ASTM F1249 is the U.S. standard that pioneered the infrared sensor approach for WVTR, and ISO 15106-2 is its international counterpart, defining the identical Infrared Detection Sensor Method.

Gas Transmission Rate: ASTM D1434 and ISO 15105-1

The standards ASTM D1434 and ISO 15105-1 are highly related, as they both specify methods for measuring Gas Transmission Rate (GTR) through films using the classic Differential Pressure Method. While they are largely equivalent in principle, they offer slightly different procedural options within the same core technique.

Both ASTM D1434 and ISO 15105-1 define the measurement of the Gas Transmission Rate (GTR) using the Differential Pressure Method, often referred to as the Manometric Method or Vacuum Method.

The core principle involves separating a high-pressure chamber (the source of the test gas, e.g., oxygen, nitrogen, or CO2 from a low-pressure chamber (the receiving side, often initially a vacuum) using the film specimen. The pressure difference is the driving force that causes gas molecules to permeate through the film. The rate at which the pressure increases in the low-pressure chamber is monitored and used to calculate the GTR, permeance, and permeability of the material. This method is highly versatile because it can be used for virtually any dry, non-corrosive, non-flammable gas. Some advanced instruments—such as those supplied by Labthink—are engineered with safety and material requirements to safely and accurately test flammable and toxic gases as well. Differential Pressure Method is the fundamental method often used for scientific research and to determine the diffusion and solubility coefficients of gases in the polymer.

While the basic principle is shared, the two standards differ in their organizational structure and the specific procedural options they include.

ASTM D1434 is titled the " Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting."It includes two procedures under its main scope: the Manometric Method and the Volumetric Method. Manometric Method is the primary differential pressure technique where the rate of pressure rise is measured on the low-pressure side of the test cell.

ISO 15105-1 is titled "Plastics — Film and sheeting — Determination of gas-transmission rate — Part 1:Differential-pressure methods." This standard is more encompassing of differential pressure techniques. It typically describes the Manometric Method as its core procedure (using a pressure sensor).

In essence, ISO 15105-1 serves as the international guidance for Differential Pressure methods, while ASTM D1434 provides a specific document detailing the Manometric (vacuum) and Volumetric (constant pressure) options.

Conclusion

In conclusion, the decision between referencing an ISO standard or an ASTM standard often depends on the specific commercial and regulatory context. While ISO provides the globally recognized framework for systems and processes, ASTM excels at defining the detailed, industry-specific technical test methods for materials. For critical material properties like OTR, WVTR, and GTR, the major standards (e.g., ASTM D3985 and ISO 15105-2) are deliberately written to be technically synonymous. Therefore, materials and equipment certified to meet one are highly likely to satisfy the requirements of the other, ensuring global consistency in assessing the quality and barrier performance of packaging films.

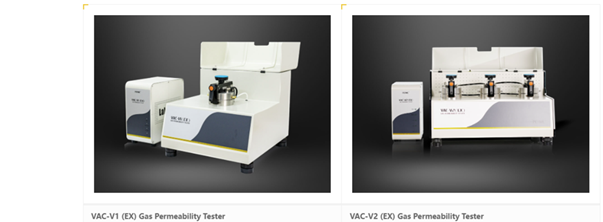

Labthink is a leading supplier of testing equipment dedicated to measuring Oxygen Transmission Rate (OTR), Water Vapor Transmission Rate (WVTR), and General Gas Transmission Rate (GTR), with instruments designed to conform to both ISO and ASTM standards. Drawing on our extensive experience and expertise in material testing, we have also developed combination instruments. These units seamlessly integrate both OTR and WVTR testing capabilities, utilizing both Coulometric and Infrared sensors in a single machine, which allows users to efficiently switch between methods and test multiple barrier properties on the same sample batch.