The food itself isprone to absorption of moisture and is easily soluble in water. When in a highhumidity environment, this kind of food will absorb water and will melt,deliquesce, and cake. Packaging of substandard quality will cause the above issues:

1) Poor barrier properties - poor water barrier properties of packaging materials causes water vapor to slowly permeate into the packaging during long-term storage.

2) Poor sealing performance – such as poor sealing properties at the sealing site caused by incorrect heat sealing parameters, as a result, water vapor enters the package through the heat sealing site. Or because the packaging is weak to high temperatures, the package leaks during sterilization, and the water vapor enters the package.

3) Inferior physical and mechanical properties - such as packaging materials are weak to punctures; or pinholes, creases, and damages on the packaging materials due to the kneading or squeezing during production and storage. If the damages were not discovered in time, the food would be exposed to a large amount of oxygen and water vapor which may lead to mold and mildew.

C306H Water Vapor Transmission Rate Test System

C306H , also water vapor permeation tester, is used for water vapor permeation analysis of packaging materials, based on infrared sensor method and ASTM F1249 and ISO 15106-2.

C303H Water Vapor Transmission Rate Test System

C303H Water Vapor Transmission Rate Tester also water vapor permeation tester, is used for water vapor permeation analysis of packaging materials, based on infrared sensor method and ASTM F1249 and ISO 15106-2.

C680M Elmendorf Tear Tester

C680M Elmendorf Tear Tester is suitable for testing tear resistance of films, textiles, paper or board based on ASTM F1922.

C650H Headspace Gas Analyzer

C650H Headspace Gas Analyzer is used to measure O2 content in MAP packages. Meanwhile, with the selection of test accessories, CO2 can also be tested.

C670M Falling Dart Impact Tester

C670M Falling Dart Impact Tester is designed to measure the impact resistance of plastic films in compliance with ASTM D1709.

C360H Water Vapor Transmission Rate Tester

C360H, also Water Vapor Permeability Tester, is designed and manufactured based on the gravimetric determination method and conforms to the requirements of ASTM E96.

C390H Water Vapor Transmission Rate Tester

C390H, also water vapor permeation analyzer, is designed and manufactured based on infrared sensor method and conforms to the requirements of ISO 15106-2 and ASTM F1249.

C330H Water Vapor Transmission Rate Tester

C330H, also moisture vapour transmission rate tester, is designed and manufactured based on the electrolytic sensor method and conforms to the requirements of ISO 15106-3.

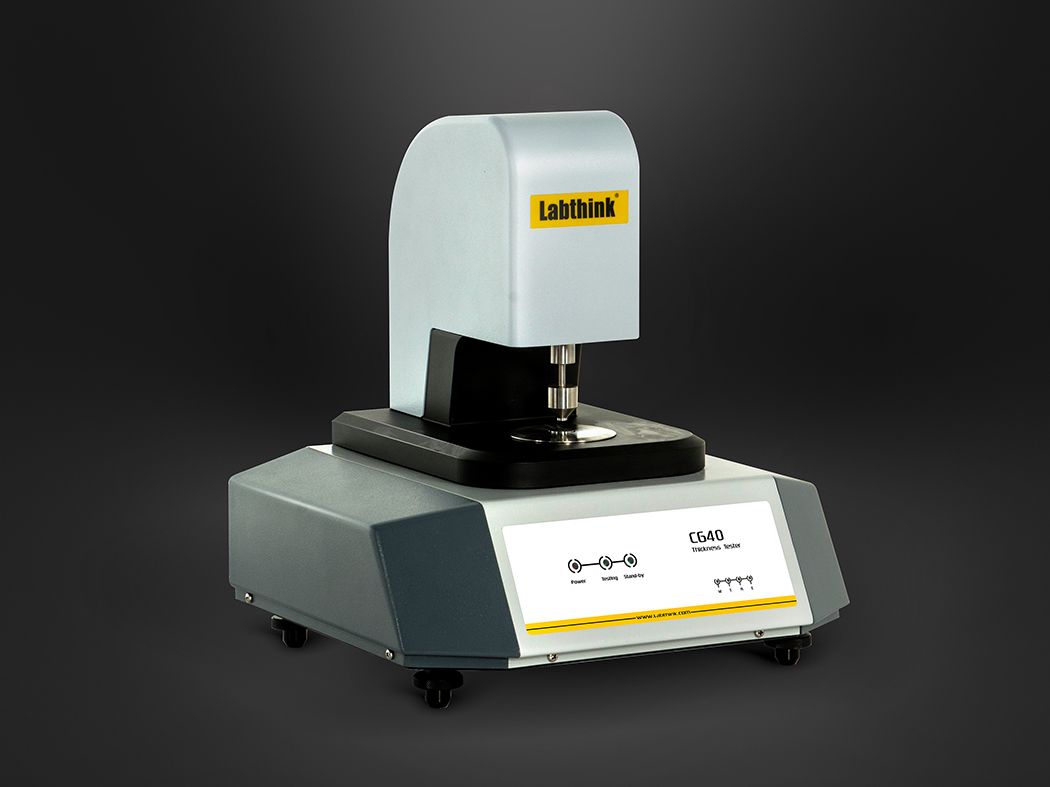

C640 Thickness Tester

C640 Thickness Tester is a high precision mechanical contact method thickness tester, which can be used for thickness measurement of films, sheeting, paper, corrugated paperboard, textiles, non-woven fabrics, and solid insulation materials, etc.

C610H Auto Tensile Tester

C610H , also tensile strength Tester is professionally used for tensile testing, seal strength testing, and etc for flexible materials. This tensile tester has high resolution and accracy.

C630H Heat Seal Tester

C630H Heat Seal Tester is applied in measuring heatsealability of a surface, or sealant layer a packing material under controlled temperature, pressure and time conditions.

C632B Hot Tack Tester

C632B Hot Tack Tester is to determine hot tack seal strength tests of packaging films according to ASTM F1921.

FIT-01 Film Pendulum Impact Tester

FIT-01 can be used to determine impact resistance properties of pendulum of plastic films, sheets, composite films, aluminum foils and other materials in accordance with ASTM D3420.

C660M Leak and Seal Strength Tester

C660M Leak and Seal Strength Tester can used for leak test, burst test and creep test of finished packages and three-side sealed packages, based on ISO 11607, ASTM F1140 & ASTM F2054.

C660B Leak and Seal Strength Tester

C660B, also vacuum leak tester is based on ASTM D3078. Using bubble emission method, the vaccum Leak Tester can be used for gross leak test of various packages and bottles.

C611M Box Compression Tester

C611M Box Compression Tester can be used to measure the compressive resistance, deformation and stacking capability of corrugated cartons and box packages.

C681M Flex Durability Tester

C681M Flex Durability Tester (Gelbo Flex Tester) is professionally applicable to the determination of flex durability of flexible films, composite films and coating films.