EVENTS & EDUCATION

Explore Labthink's latest events and knowledge sharing in packaging testing — click Contact us to get professional insights on testing instruments.

NEW & FEATURED INSTRUMENTS

The latest testing instruments developed by Labthink offer higher testing efficiency and more advanced features. Consult our professionals if you have any questions about selecting the right equipment.

The C403H is an advanced permeability tester developed by Labthink for high-precision packaging testing applications.As intelligent lab testing equipment, it provides a reliable, automated, and efficient solution for package testing, ensuring accurate evaluation of material barrier properties.

Dual-function testing: Measures both oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) of flexible packaging materials with continuous detection on a single sample.

High efficiency: Tests up to three samples simultaneously with fast results, typically completed within 24 hours.

Smart control: Full system automation with sample changing possible without downtime and precise temperature control unaffected by environmental fluctuations.

Versatile testing: Supports container testing and uses standard nitrogen as carrier gas.

Reliable performance: Detection sensor includes a six-year warranty, setting a benchmark among packaging testing instruments from a leading testing instruments supplier.

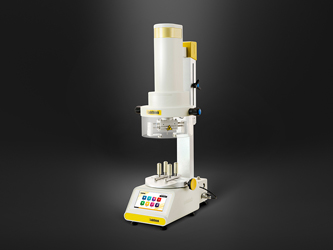

The C406H is an advanced permeationanalyzer designed for high-precision packaging testing. This intelligent labtesting equipment delivers automated, dual-function measurement of oxygen (OTR)and water vapor (WVTR) transmission rates.

Tests up to six samples simultaneously with continuous dual-parameter detection.

Intelligent control and precise temperature regulation ensure stability.

Supports multi-gas permeability testing with standard nitrogen as carrier gas.

Routine testing completed within 24 hours.

Backed by a six-year sensor warranty.

C130H Gas Permeability Tester - an advanced permeation analyzer for flexible packaging materials.

Functionality: Determines gas transmission rates of O2, N2, CO2, and other gases for gas permeation test and package testing.

Efficiency: Tests three samples simultaneously with 24-hour routine operation.

Intelligent Control: Fully automated system with stable temperature regulation,unaffected by environmental changes.

Reliability: Equipped with a non-consumable detection sensor ensuring long-term precision.

Professional Application: Part of Labthink’s packaging testing instruments, ideal for testing service and research laboratories.

Labthink C203H Oxygen Transmission Rate Tester - a high-precision OTR testing equipment for flexible packaging materials.

Dual Function: Measures oxygen transmission rate and can be expanded to test water vapor transmission rate on the same sample.

Testing Efficiency: Tests three samples simultaneously and completes within 24-hour via routine operation.

Intelligent Control: Fully automatic system with temperature stability unaffected by environmental changes.

Flexible Operation: Samples can be replaced without shutting down; containers can also be tested.

Reliability: Uses ordinary N2 as carrier gas with a six-year-guaranteed detection sensor.

Labthink C303H Water Vapor Transmission Rate Tester is an automatic and efficient solution for packaging testing and permeability testing of flexible materials. It supports precise Testing Instruments and Testing Service applications in the packaging industry.

Dual Functionality: Measures water vapor and optional Oxygen transmission rate for two indexes of one sample.

High Efficiency: Tests three samples at once, enhancing productivity for packaging testing instruments users.

Intelligent Control: Fully automatic with stable data performance, ideal for permeation analyzer applications.

Non-stop Operation: Sample scan be changed without shutting down the system.

Temperature Stability: Constant system temperature unaffected by the environment ensures reliable package testing results.

Fast & Versatile: Routine test within 24 hours suitable for films and containers; carrier gas can be ordinary N2.

Reliable Sensor: High-stability detection sensor with six-year guarantee.

Labthink C690H Non-destructive Package Leak Detector is based on the package leak testing principle of the vacuum decay method, designed and manufactured according to ASTM F2338 and other standards. It is professionally suitable for batch sealing leak detection of vials, and trace leakage detection of ampoule, cartridge bottles, infusion bottles, prefilled syringes and other pharmaceutical and medical package testing.

Labthink C230H Oxygen Transmission Rate Tester is a classic solution for oxygen permeability testing of flexible packaging materials. As a high-precision oxygen permeation analyzer, it provides accurate and efficient results in the packaging testing field.

Three samples are tested at a time.

Test is completed within 24H (routine).

Containers can be tested.

Carrier gas can be ordinary N2.

Six-year-guarantee for the detection sensor.

Labthink C390H Water Vapor Transmission Rate Tester is a classic and reliable WVTR testing machine ideal for flexible packaging testing.

Three samples are tested at a time.

Test is completed within 24H (routine).

Containers can be tested.

Carrier gas can be ordinary N2.

Six-year-guarantee for the detection sensor.

Labthink C360H Automatic Water Vapor Transmission Rate Tester measures various packaging films and flexible materials using the cup method (gravimetric method). It integrates the entire automatic process of heating, water vapor generation, and transmission measurement.

Twelve samples are tested at a time.

Desiccant Method and Water Method.

Errors caused by manual operation are eliminated.

Detection efficiency is greatly improved.

Labor costs are greatly reduced.

A classic, high-precision and specialized solution for tear resistance testing of flexible packaging materials and a variety of non-metallic flexible materials.

Computer control.

Electron optical measurement.

Automatic sample loading.

Pendulum is automatically released.

Professional data operation model.

Test results of multiple modes can be obtained.

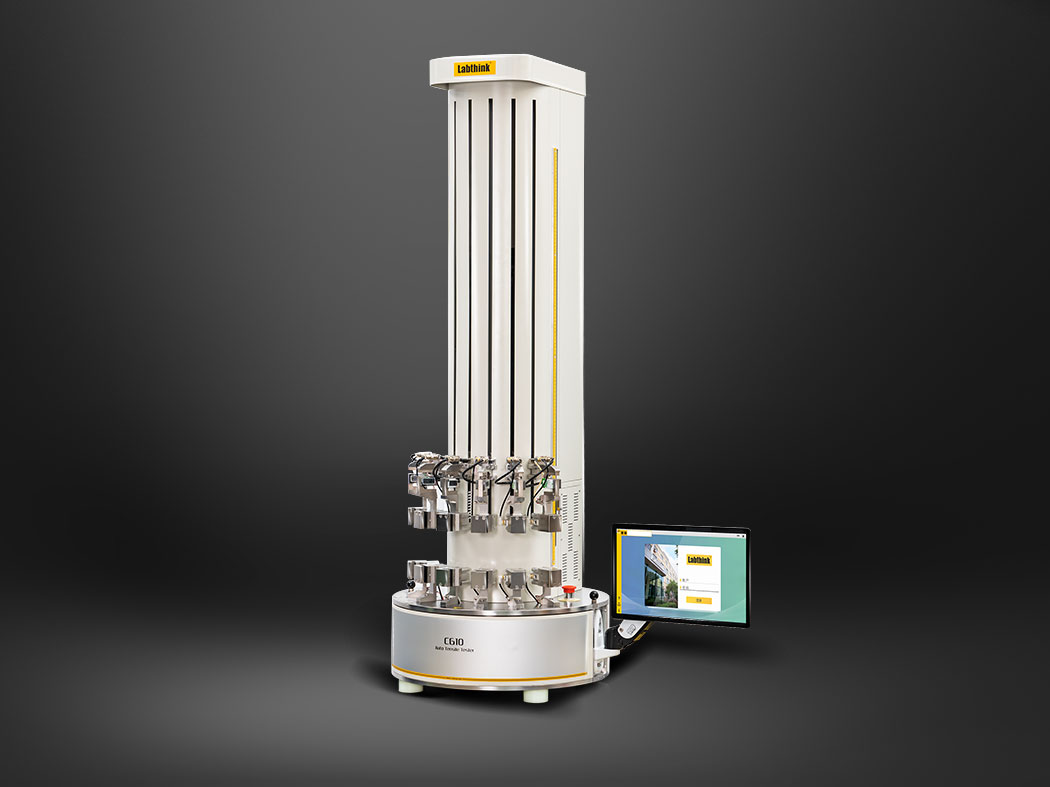

A specialized solution for various tests on mechanical strength of flexible packaging materials.

A large range of 1000mm.

Tests for large deformation materials can be realized.

Tensile, peeling and bonding, etc. can be realized.

Flexible packaging professional data operation model.

Test results of multiple modes can be obtained.

Labor is greatly reduced.

A high-precision and specialized solution for the dual measurements of coefficient of friction for flexible packaging materials and the peel strength of adhesive composite products.

Resolution is up to 0.001N.

Tests of both coefficient of friction and peel strength.

High temperature test and automatic temperature control.

Flexible packaging professional data operation model.

Test results of multiple modes.

An efficient solution for the determination of optimal heat sealing time, heat sealing pressure and heat sealing temperature of plastic films, composite films and other heat sealing materials.

Five groups of tests for different parameters can be realized at one time.

Temperature of the ten upper and lower heat heads can be controlled individually.

Best heat sealing parameters can be quickly selected.

Both manual and pedal start modes.

Anti scald safety design.

A classic solution for the accurate determination of pendulum impact resistance of plastic films, sheets, composite films, metal foil and other materials.

Electron optical measurement.

Automatic sample loading.

Automatic release of the pendulum.

Multiple test conditions.

Intelligent data statistics.

External connection and data transmission can be realized.

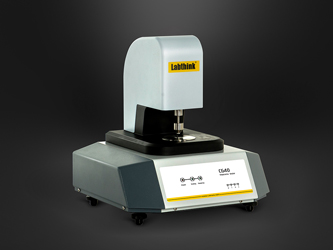

A high-precision and automatic solution for the thickness measurement of flexible materials such as films and sheets, etc.

Resolution is up to 0.1μm.

Automatic sample input.

Measurement spacing, sample advancing speed and measurement points can be set.

High efficiency continuous multipoint measurement.

Intelligent data processing.

A high-precision and automatic solution for the determination of heat shrinkage force, cold shrinkage force and heat shrinkage rate of packaging heat shrinkable films in the shrinkage process.

The sample enters and exits the high-temperature chamber automatically.

Force value sensitivity is up to 0.001N.

Advanced laser length measurement.

Real time display of test data.

Global standards are met.

An efficient solution for the test of anti rubbing performance of flexible films, composite films, coating films and other materials.

Four samples are tested at a time.

Five standard tests.

Long and short stroke switching.

Number of test times can be set freely.

Ambient temperature and humidity can be recorded automatically.

Dual safety protection by software and hardware.

A specific and automatic solution for the measurement of cap locking and opening torque of bottles, those with nozzles and soft tube packaging.

Dual test modes of opening force and locking force.

Clamping force, locking force and rotation speed can be set freely.

Locking deviation <0.01 nm.

Manual test and automatic test can be selected.

Overload protection, automatic zero and fault prompt.

Safety shield.

A professional and multipurpose solution for the quantitative determination of sealing strength, heat sealing quality, whole bag bursting pressure and sealing leakage performance of various flexible packaging and sterile packaging.

Four test modes: rupture, creep, creep to rupture and pressure holding.

Double test methods of expansion inhibition and expansion non-inhibition.

Real time monitoring of intake air flow.

Real time display of test curve.

Intelligent data statistics.

Test units can be changed freely.