- PRODUCTS

- Product Index

- Product Index

- New & Featured Instruments

- By Test Standard

- ISO Standards

- ASTM Standards

- TAPPI Standards

- Other Standards

- Testing Software

- Datashield

-

SOLUTIONS

- Classified by packaging materials

- Bag packaging

- Bottle / barrel container

- Carton Packaging

- Packaging Solutions

- Bag packaging

- Bottle/barrel container

- Carton

- Fine Chemicals

- Fine Chemicals

- Solutions for Researching Institutes

- Solutions for Researching Institutes

- Solutions for Inspection Institutions

- Solutions for Inspection Institutions

- TESTING SERVICES

- NEWS & EVENTS

- LITERATURE

- ABOUT US

- CONTACT US

- LANGUAGE

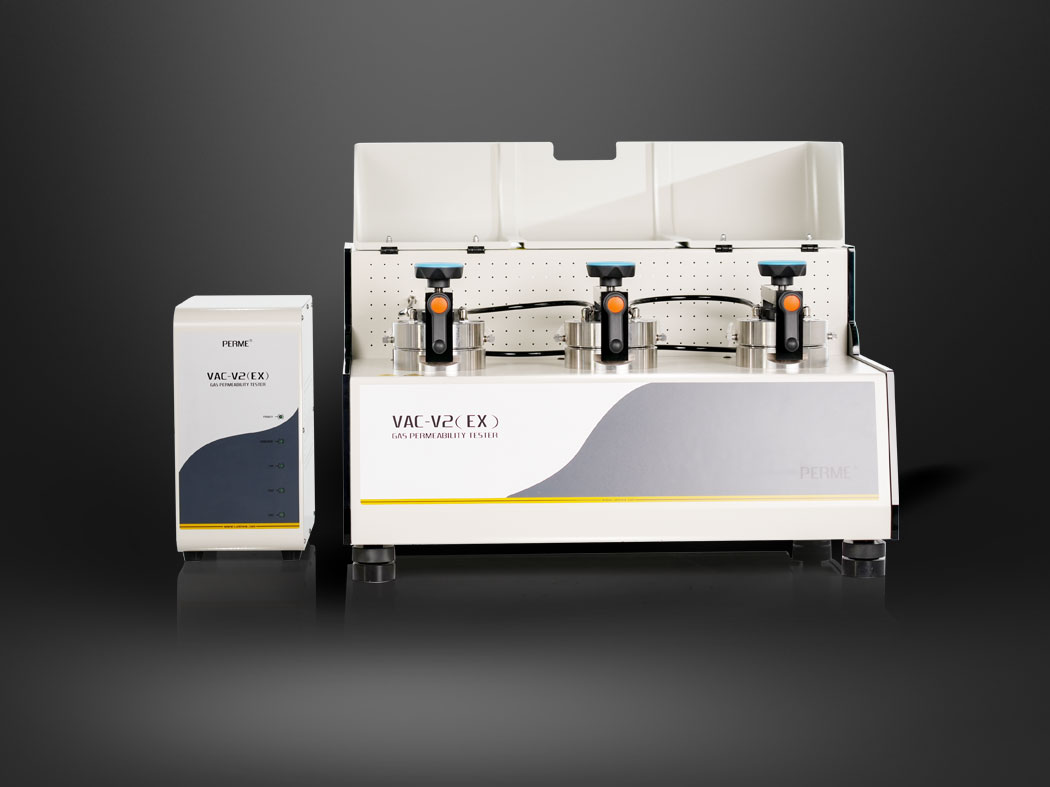

VAC-V2 (EX)-H Gas Permeability Tester

VAC-V2 (EX)-H Gas Permeability Tester is based on the differential pressure method, and is professionally applicable to the determination of gas transmission rate of common gases as well as toxic, flammable or explosive gases. It is suitable for the determination of gas transmission rate, solubility coefficient, diffusion coefficient and permeability coefficient of plastic films, composite films, high barrier materials, sheeting, and aluminum foils at varied temperatures.

Product Features

- Labthink advanced split control system is applied to realize complete separation of the tester mainframe and control module so as to ensure testing safety.

- The tester is suitable for gas transmission rate determination of flammable, explosive or toxic gases.

- The tester can perform permeability tests in normal pressure and high pressure conditions

- The tester has passed TUV safety certification.

- Three independent test cells can test three identical or different samples simultaneously.

- Gas transmission rate, permeability coefficient, solubility coefficient and diffusion coefficient are determined simultaneously.

- Wide-range & high-precision liquid circulation temperature controller can satisfy tests under varied test conditions.

- Dual testing process judgment patterns are available: Proportional Mode and Fuzzy Mode.

- Data fitting at any temperature can be performed; test results under extreme conditions can be obtained easily.

- PC-controlled, and the whole test process can be accomplished automatically.

- Reference film is available for rapid calibration to ensure the accuracy and versatility of the test data.

- RS232 universal data port is equipped to facilitate data transfer.

- The tester is compatible with Lystem Laboratory Data Sharing System with unified management of test results and test reports.

Principle

VAC-V2 (EX) -H Gas Permeability Tester is designed based on the differential-pressure method. The pre-conditioned sample is mounted in between the upper testing chamber and lower testing chamber and clamped. First, the lower-pressure chamber (i.e., lower testing chamber) is evacuated, followed by the evacuation of the entire system. When the desired vacuum degree is achieved, close the lower testing chamber and test gas of a certain pressure is flushed to the higher pressure chamber (upper testing chamber), and a constant pressure difference (adjustable) is generated between the two testing chambers. The gas permeates through the sample from the high pressure side into the low pressure side due to pressure gradient. The gas permeability parameters of the sample can be obtained by monitoring the pressure changes in the lower testing chamber.

Standards

This test instrument conforms to the following standards:

ISO 15105-1, ISO 2556, GB/T1038-2000, ASTM D1434, JIS K7126-1, YBB 00082003

Applications

This test instrument is applicable to the determination of gas permeability of:

| Basic Applications |

|---|

Including plastic films, plastic composite films, paper-plastic composite films, coextruded films, aluminized films, aluminum foils, aluminum foil composite films and many others |

Including engineering plastics, rubber and building materials, e.g. PP, PVC and PVDC |

| Extended Applications |

Test the permeability of various types of gases, e.g. O2, CO2, N2, Air and He |

Test the permeability of inflammable and explosive gases |

Test gas permeability of various sorts of biodegradable films, e.g. starch-based biodegradable bags |

This instrument can test the Helium permeability of airship gas bags |

Test gas permeability of paper and paper-plastic composite materials, e.g. aluminized paper for cigarette packages, Tetra Pak sheeting, paper bowls for instant noodles and disposable paper cups |

Test gas permeability of substrates coated paint films |

Including glass fiber cloth and paper materials, e.g. Teflon paint cloth, Teflon welding cloth, and Teflon silicon rubber cloth |

Including various types of cosmetic tubes, aluminum-plastic tubes and toothpaste tubes |

Including various sorts of rubber sheeting, e.g. car tires |

Technical Specifications

| Specifications | Film Test |

|---|---|

| Test Range | 0.05 to 50,000 cm3/m2·24h·0.1MPa (standard volume) |

| 0.05 to 1,000 cm3/m2·24h·0.1MPa (extended volume) | |

| Number of Specimens | 3 pieces (with respective data) |

| Vacuum Resolution | 0.1 Pa |

| Vacuum Degree of Test Chamber | <10 Pa |

| Temperature | 5℃~95℃ |

| Accuracy | ±0.1°C |

| Specimen Size | Φ50 mm |

| Test Area | 5 cm2 |

| Test Gas | H2, O2, N2 and CO2 (outside of supply scope) |

| Test Pressure | 100 kPa ~ 3000 kPa |

| Gas Supply Pressure | 0.5 MPa~0.6 MPa |

| Port Size | 1/8" Metal Tube |

| Instrument Dimension | 760 mm (L) × 575 mm (W) × 450 mm (H) |

| Power Supply | 220VAC 50Hz |

| Net Weight | 88 kg |

Configurations

- Standard Configurations

- mainframe, thermostat controller, computer, professional software, special sampler, vacuum grease, fast quantitative filter paper, vacuum pump (inlet)

- Optional Parts

- Sampling blade, vacuum grease, vacuum pump oil, rapid quantitative filter paper

- Note

- The air source inlet of the tester is a 1/8" metal pipe; the gas sources are to be provided by the users.

We can help you select or customize the proper unit for your test requirements.

Related Products

Product Categories

Search Products

Have a question or need assistance?

Discover how Labthink's testing instruments and packaging testing services can help your company improve efficiency and product quality. For expert support with packaging testing instruments, click the button to contact our experts and submit your inquiry today.